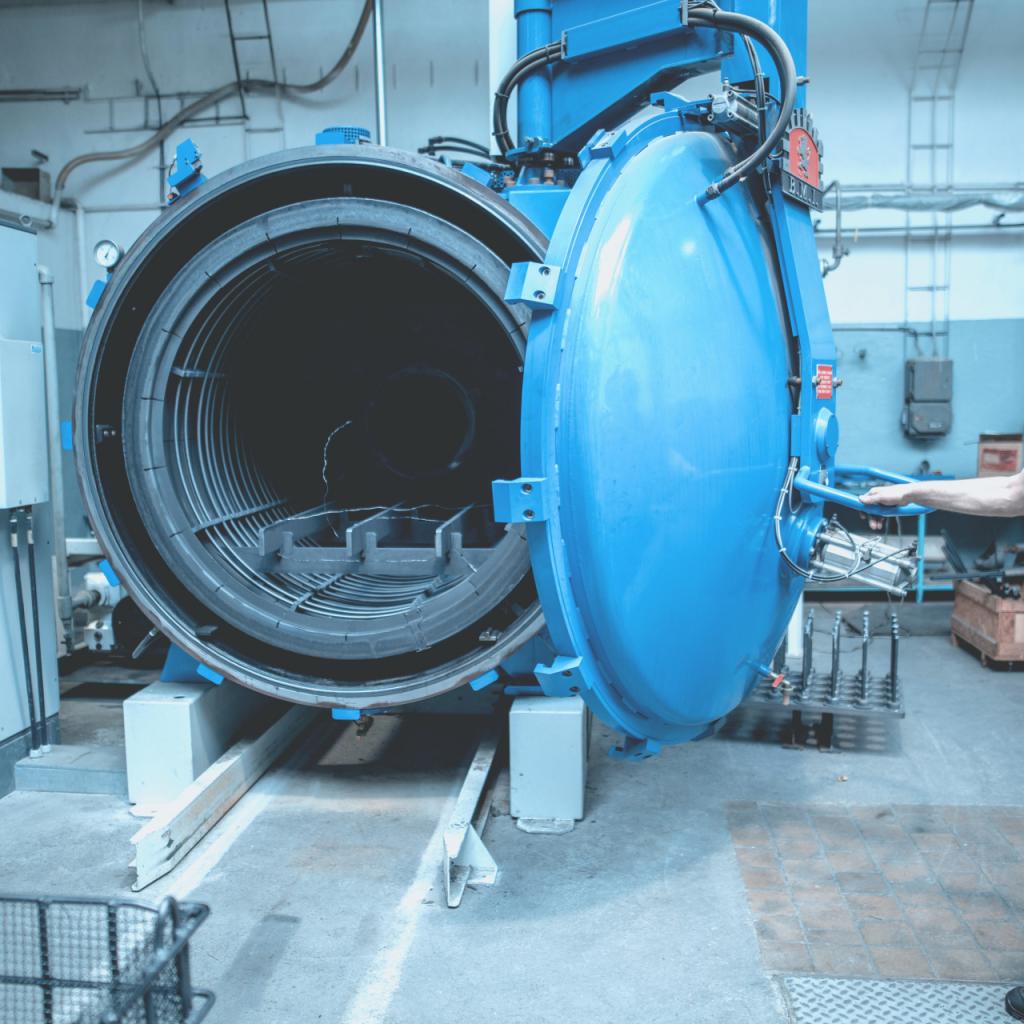

- Heat and chemical & heat treatments of structural, tool and high-speed steels.

- Annealing and precipitation hardening of special aircraft materials according to AMS.

- Annealing and tempering in a protective endoatmosphere.

- Blasting with iron grit, ballotini impact beads.

- Metallographic and spectral analyses.

Heat treatment consulting. The quality of process manufacturing is checked and recorded in accordance with the applicable ISO and AMS standards. Capability to print records of processes, structures, percentages of components and chemical analyses of materials.